Consumer preferences and budgets are changing, and tilers and merchants need products to keep up with the demand.

According to research commissioned by the Bathroom Manufacturers Association, the average UK bathroom renovation budget has steadily increased over the last ten years, now averaging around £7,500 per project. The cost-of-living crisis, however, means a customer’s budget is a much larger portion of their expendable income, while increases in the cost of materials and services stretch their budgets even further.

This has increased the need for “done and dusted” or “fit and forget” installations. Customers’ budgets don’t go as far, tilers can’t afford to revisit and repair jobs, and merchants must provide quality products that can be relied on. When it comes to electric underfloor heating, the way to avoid this worry is by using cables that allow for quicker, quality workmanship and remove the risk of damage to cables during installation.

One of the most common points of failure in an underfloor electric heating installation is the hot-to-cold joint. This is the point where the heated cable that goes under the tile or stone floor meets the non-heated cable (i.e., the cold cable) that runs to the thermostat in the wall. Depending on the brand, the hot-to-cold joint can be three times the size of the heating cable. This is because it is created during a secondary manufacturing process where the two cables are crimped or soldered together and wrapped in heat shrink.

These bulky hot-to-cold joints prevent installers from easily making a flush surface ready for tiling and requires them to bore out cavities to accommodate their size. The method to do this requires cutting through the underfloor heating membrane mat, carving out insulation board, or even chasing out the concrete, wooden or tiled floor. Using sharp tools to install the cable can lead to damage during installation. Creating cavities under the cable and joint results in air pockets that don’t allow heat to escape properly, leading to overheating and failed cables months or years down the line.

Having to revisit underfloor heating projects due to damaged cables is costly. What’s more, it can also be a frustrating and complex process as, once an underfloor membrane is compromised or a heating cable is damaged, the product warranties are normally void, making installers responsible for the fault and replacement of the materials.

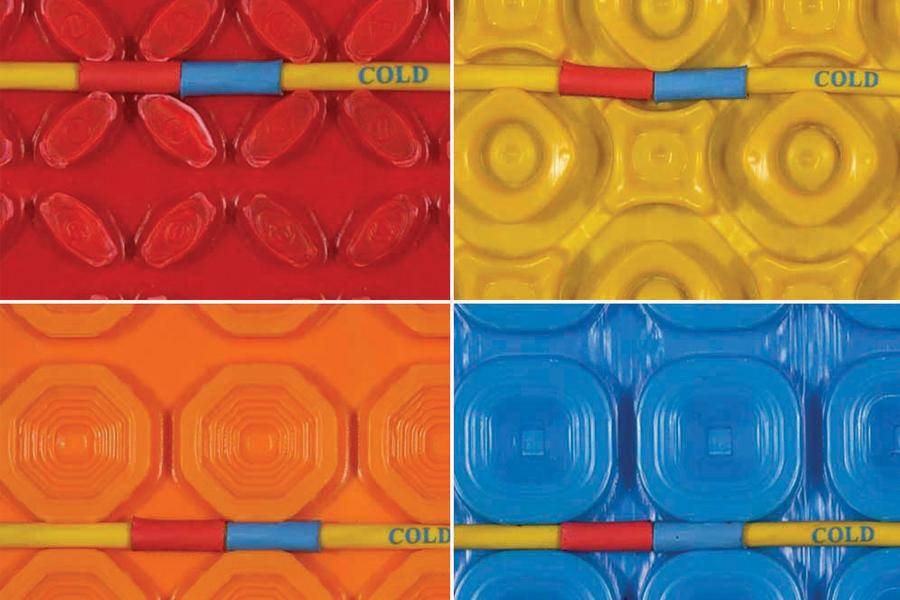

To allow installers to avoid the headache and costs of returning to a finished job, ThermoSphere has created what it says is a first-of-its-kind Membrane Heating Cable designed to drastically transform the electric underfloor heating installation process and effectively eliminate the risk of joint failure altogether. The Membrane Heating Cable is said to be the first cable to use TwistedTwin construction alongside in-line joint technology, creating a cable that is one thickness end-to-end, and significantly more robust than non-twisted cables. Getting rid of the joints and having a uniform 4mm diameter cable reportedly removes the need for installers to use grinders or Stanley blades altogether. Installers simply thumb-press the cable into the heating membrane mat, making it virtually impossible to damage during installation.

Thanks to the introduction of four cable sizes (42m, 55m, 90m and 175m) installers now have a cable for every project and can reduce the number of multi-cable installations they perform. And, because installation is a one-step, tool-free process, tilers can press in the single cable and be done, letting them move quickly on to the rest of the job and minimise disruption to the customer’s home. Additionally, the cable fits with all decoupling membrane mats on the market, the company says, so tilers can rely on the products they are familiar with, and customers don’t need to pay inflated prices for specialist products.

www.thermosphere.com/thermosphere-membrane-cable-press