Leading Polish tile manufacturer Ceramika Paradyż has invested in a new production line as part of a project co-funded by the EU.

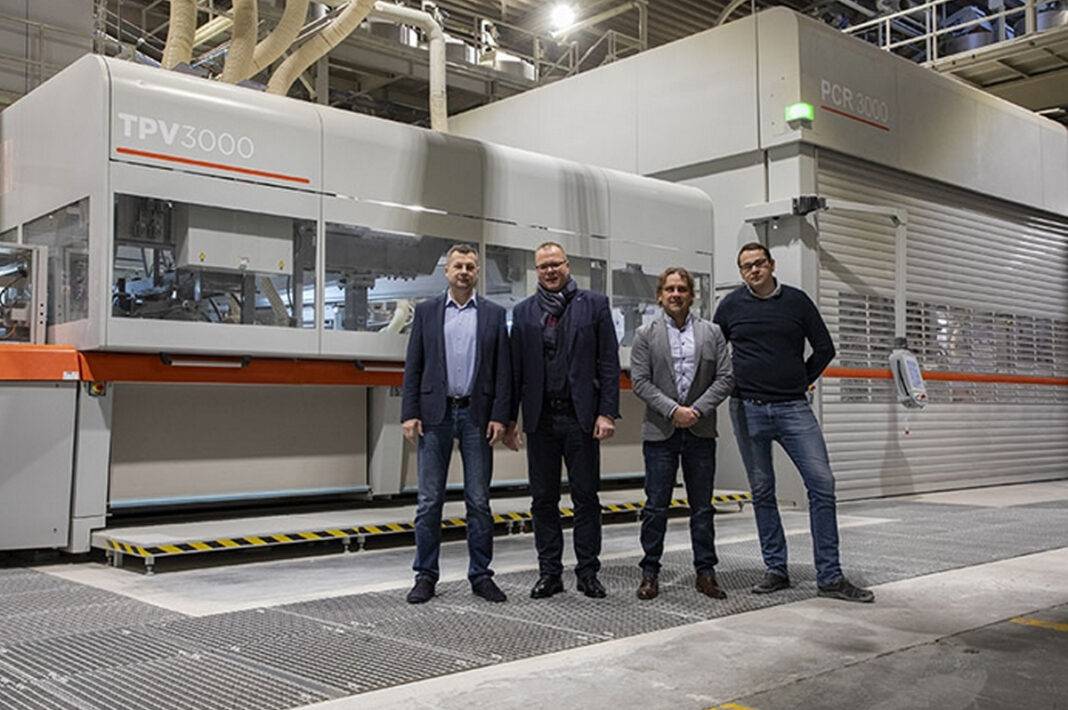

At the heart of the new plant is a new Continua+ line for the production of tiles and slabs in various sizes, and thicknesses up to 30mm. Sacmi supplied a Continua+ PCR 3000 compactor capable of producing through-body veining, allowing manufacturers to perfectly co-ordinate the coloured powders deposited upstream from the compactor with any digital decoration on the unfired slab.

“We now have the most advanced line in Europe,” says Piotr Tokarski, Chairman of Ceramika Paradyż. “It allows us to produce tiles in sizes from 600 by 600mm to 1,200 by 2,800mm, and even 1,800 by 3,200mm, and in thicknesses ranging from 6mm to 30mm, as well as to perform through-body decoration on some sizes.”

Sacmi also supplied the other machines, including the dryer, the kiln, the handling systems and the glazing and sorting lines. One of these is the DHD1408 digital decorator, complete with all the innovative systems necessary for perfect coordination with in-body decoration when manufacturing products with through-body veining.