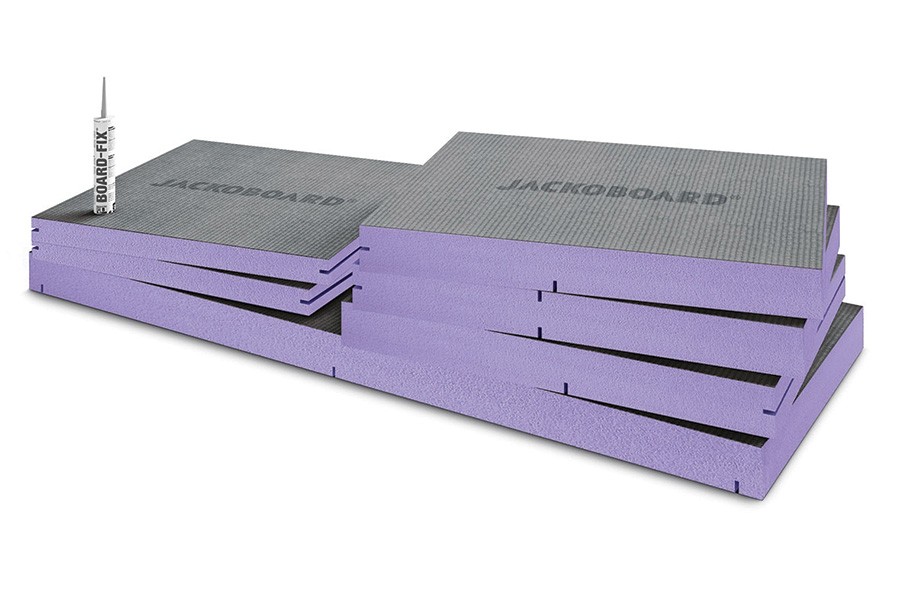

Jackoboard from BEWI is said to offer many benefits for installers of wetrooms and bathrooms. The product is a waterproof, weight-loading and thermally insulating construction board for use in all types of tiling jobs.

It’s also the best solution for tile fixers, builders and wetroom installers, BEWI says, in the light of 2023 guidance from the National House Building Council (NHBC) which comes into effect this month.

NHBC Standards 2023 Clause 9.2.5 “Ceramic wall tiling” advises that gypsum plasters should not be used where repeated or persistent wetting may occur and also that in wet areas e.g. showers, backing surfaces may require protection with a suitable tanking system.

NHBC introduced this guidance due to a rise in claims relating to the walls surrounding baths, shower enclosures and bathroom pods. It was reportedly obliged to act because, although claims on new builds are covered by builders’ warranties for up to two years, after this point, homeowner claims become the responsibility of NHBC.

“Problems mostly arise due to inadequate tanking,” says Mike McCann, business development director at Jackoboard, “and there is a certain ambiguity here, since a waterproof backerboard is not explicitly specified, which is the best solution for the entire wetroom area. Unfortunately some builders will only tank with a silicon up to a one metre height, and this is not adequate, more or less guaranteeing problems down the line. The key thing is to spend a little bit more upfront in order to ensure a longlasting and problem-free installation.

“Another point is that there is a distinction made in the guidance between powered and non-powered showers,” continues McCann. “At Jackoboard we don’t necessarily think this is helpful, as it tends to create confusion and ambiguity. Who’s to say somebody won’t install a power shower at some later stage and probably be unaware of the type of tanking that has been used behind the tiles? The best solution therefore is an XPS backerboard for all bathroom and wetroom installations.”

Jackoboard offers several benefits, according to BEWI, such as superior weight loading. This is significant at a time when large format and heavier tiles are increasingly popular. At 100kg/m, the weight loading offered by Jackoboard is reportedly more than three times that offered by plasterboard. It’s also said to offer excellent insulation properties and reduce cold bridging when used on external walls.

Because the product is manufactured from 100% waterproof XPS, there is no need to tank entire wetrooms constructed using Jackoboard, BEWI says, either with a waterproof membrane or a paint-on solution. This saves the installer both time and money, since a separate tanking system is not required and only the joints where the boards meet and any mechanical fixing points need to be tanked (Jackoboard provides a sealing kit for this purpose).

Although the NHBC Standard states: “Backing surfaces may require protection from a suitable tanking system”, which is entirely correct, it should not be interpreted to mean that if you are using an XPS backerboard, such as Jackoboard, you have to tank the entire substrate of your wetroom. The closed structure of an XPS board is said to ensure it is totally impossible for water to pass through it, the way it would through a fibre cement board for instance.

This also means that Jackoboard additionally offers a time and cost-saving benefit for installers on site.

Jackoboard is keen to communicate these key messages to the different trades who get involved in the installation of wetroom systems, from the shower tray upwards. Although there are wetroom specialists, this job is often down to plumbers, M&E contractors, tilers, dryliners and flooring contractors. So, as wetrooms continue to increase in popularity, there are different trades who need to be aware of the benefits of XPS backerboards.

While offering the benefits of XPS, Jackoboard can also offer a price advantage in the marketplace, BEWI says, due to the fact that the company manufactures its own foam, giving it complete control over cost, product quality and sustainability of manufacturing processes.

www.bewi.com/uk

jackoboarduk@bewi.com