Said to be the sustainable choice in construction boards, JACKOBOARD construction systems have now joined the BEWI portfolio.

BEWI is an international provider of packaging, components, and insulation solutions, with what it calls an especially strong commitment to sustainability. This is integrated throughout the value chain, from production of raw materials and end goods, to recycling of used products. “With a vision to protect people and goods for the future,” the company says, “BEWI is leading the change towards a circular economy.”

The company says it views its significant annual purchasing volume as an opportunity to drive change and to increase the emphasis on sustainability in the value chain. Though setting clear goals and actively collaborating with suppliers, the company works to ensure that its procurement reflects its goals linked to resource efficiency, circularity and social responsibility.

Transport is a large part of the value chain, accounting for much of the company’s CO2 emissions. It’s constantly working to reduce the impact from its transport operations by creating cleaner and leaner logistics. BEWI says it works to optimise routes, fill vehicles more efficiently and work with logistic providers to implement non-fossil fuel alternative transport options.

The company is committed to becoming circular. It continuously works to increase its collection capacity both through its own investment and also by collaborating with its customers and partners to ensure that its products are sorted out for collection and that the logistics are in place for the recycling of materials.

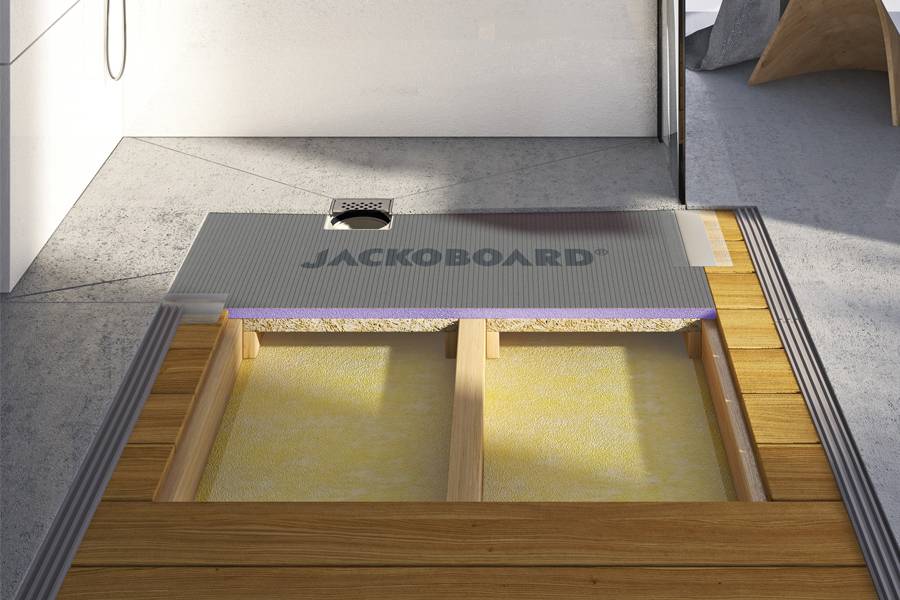

The JACKOBOARD construction boards themselves comprise 98% air and are 100% recyclable, meaning they provide excellent insulation and can help to improve the sustainability of houses, the company says, while driving down heating costs. The extruded polystyrene (XPS) from which they are made is said to be a very long-lasting material, which is inert and does not leak liquids or gases.

The product is designed to provide the flexibility to meet modern requirements in bathroom design for both commercial and domestic projects. Each board features an extruded XPS polystyrene core with a special coating on each side. This is said to ensure the boards form an ideal substrate for ceramic, porcelain, or natural stone tiles. They are also waterproof, meaning only the joints need to be tanked, again saving on materials and reducing environmental impact. The boards are thermally insulating, easy to shape, truly lightweight and strong.

The latest British Standard for tiling requires the wider use of more appropriate materials for construction, and for receiving tiles in water sensitive and wet areas. This has increased the demand for the JACKOBOARD range in new build applications as well as in renovation works.

When the JACKOBOARD product range is used in new builds or extensions which are constructed using the BEWI Building Systems, the company says, these buildings can be made to meet the latest Part L regulations, which are designed to cut carbon emissions from houses by 31%.

The range also reportedly enables such dwellings to exceed the requirements of the Future Homes Standard, which is coming in by 2025 and will require 75-80% less carbon emissions than currently.

This product range not only has BBA approval but also Passivhaus certification, meaning the products can play a role in the drive towards net zero house construction.

01204 221089